4axis Multi-heads spindle router cnc engraving cutting machine with rotary device for Wood MDF Furniture Decoration

* A Wide range of spindles options(from 2 to 20pcs),

will process several materials at one time, which greatly increases the working efficiency.

* Constructed from heavy,all-steel tube frame along with thicken steel gantry that ensure durability.

It also features cast steel gantry supports which greatly dampen vibrations and improves routing quality.

* Use Professional high-temperature artificial aging treatment to eliminate welding stress,

high precision machining planer ensures strong, durable with no deformation.

* XY axisfeatures high-precision helical racks and Z axis features ball screw to provide

smooth motion and tight control for precise and quality engraving.

* Y-axis adopt dual-motor drive, powerful and smooth operation.

* The use of breakpoint memory ensures the continuing of processing in case of accidents.

Such as cutter broken, power failure and stuck unforeseen.

* Just a touch of the automatic lubrication system, easy to complete regular maintenance.

* Compatible with any advanced CAM/CAD software,

such as Type3, Artcam,CAXA,Pro-E,UG, Artcut, Mastercam.

* Adopt NCstudio CNC system, keyboard operation, large screen display, easier to operate

and maintain, more humanized design

1. Advertising industry

Signage; Logo; Badges; Display board; Meeting sign board; Billboard

Advertising filed, sign making, acrylic engraving and cutting, crystal word making, blaster molding, and other advertising materials derivatives making.

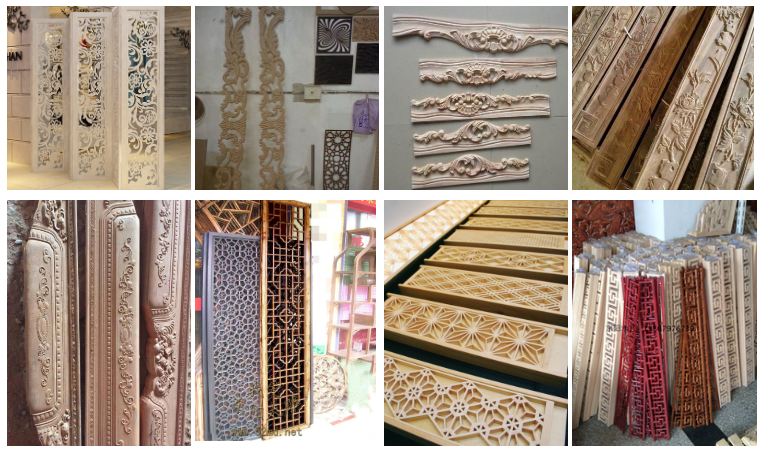

2. Wood furniture industry

Doors; Cabinets; Tables; Chairs.

Wave plate, fine pattern, antique furniture, wooden door, screen, craft sash, composite gates, cupboard doors, interior doors, sofa legs, headboards and so on.

3. Die industry

A sculpture of copper, aluminum, iron and other metal molds, as well as artificial marble, sand , plastic sheeting, PVC pipe, and other non-metallic mold.

4. Artwork and Decoration

wood crafts; gift box; jewelry box

5. Others

Relief sculpture and 3D engraving and Cylindrical object.

| Description | Parameter |

| Model | UW-FR1513-6 |

| X,Y,Z Working Area | 1500x1300x200mm |

| Control system | Mach3/DSP 4 axis Control System |

| Table Surface | T-slot clamping working table |

| Spindle | Changsheng 1.5/2.2kw Water Cooling Spindle |

| X, Y Structure | Taiwan HIWIN Linear guide rail and helical rack |

| Z Structure | Ball screw and Taiwan HIWIN Linear guide rail |

| Driver and Motor | Servo driver and motor |

| Rotary axis | Can be customized. |

| Inverter | Fuling Inverter |

| Max. Rapid Travel Rate | 45000mm/min |

| Max. Working Speed | 30000mm/min |

| Spindle Speed | 0-24000RPM |

| Lubrication system | Automatic oil pump |

| Command Language | G Code |

| Computer Interface | USB |

| Collet | ER16 |

| X,Y Resolution | <0.01mm |

| Software Compatibility | Type3/Artcam Software |

| Running Environment Temperature | 0 - 45 Centigrade |

| Relative Humidity | 30% - 75% |

| Optional | Italy air cooling spindleJapan YASKAWA servo motor and driver

Leadshine servo motor and driver Delta inverter DSP/WEIHONG system Vacuum air adsorbing 2 in 1 table |

Packing:

Firstly, packed the cnc router machine with plastic sheet for clearing and damp proofing.

Secondly, then put the cnc router machine in the plywood case for safety and clashing.

Thirdly, transport the plywood case into the container.

Technical support:

1. Our technician can give you remote guide online(Skype or WhatsApp) if any question.

2. English version manual and operation video CD disk

3. Engineer available to service machinery overseas

After sales services:

Normal machine is properly adjusted before dispatch. You will be able to use the machine immediately after received machine.

Besides, you will be able to get free training advice towards our machine in our factory. You will also get free suggestion and consultation, technical support and service by email/skype/tel etc

You can tell us the working piece material, size, and the request of machine function. We can recommend the most suitable machine according to our experience.

Other kinds of payment we can consider if acceptable for us.

For standard machines, it would be about 7-10 days. For customized machines according to your specific requirements, it would be about 15-20 working days.

After we confirm all details ,then You can pay 30% deposit according the Proforma invoice, then we will start to make production. Once the machine is ready , we will send pictures and video to you, and then you can finish the banlance payment. Finally, we will pack machine and arrange delivery for you as soon as possible.

Firstly , when you got machine , you need to contact with us ,our engineer will together with your to deal with it ,secondly ,we send user manuals and

CD to you before you get the machine ,Thirdly Our professional technician online teach you until you can use it well by yourself.

1) T/T, means international bank transfer. 30% deposit, we produce the machine for you. 70% before shipping.

2)L/C at sight

3)D/P at sight