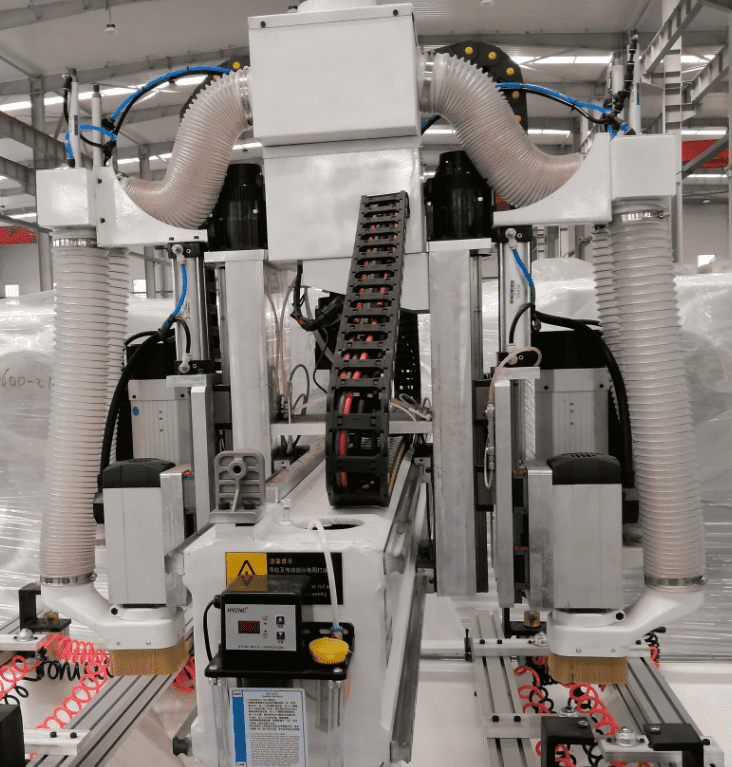

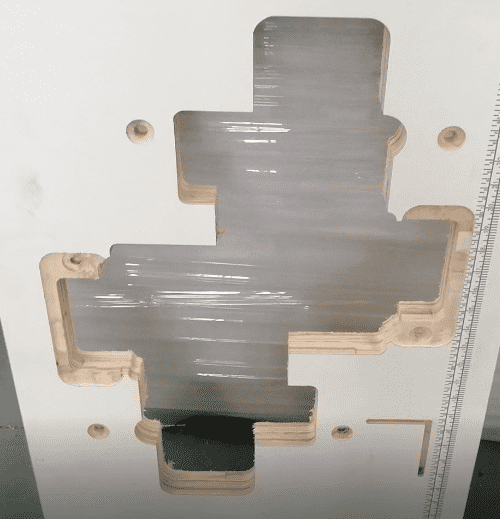

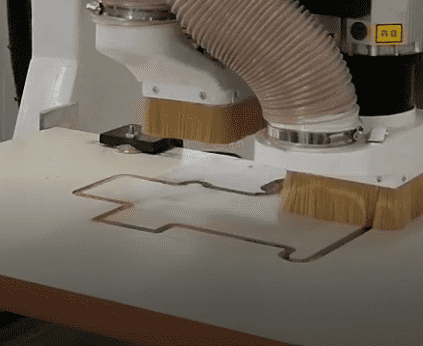

Pneumatic wooden cnc router milling Sewing machine panel cnc cutting drilling machine

1. The bed is welded with large square tube and quenched, which is more stable and will not be deformed for a long time.

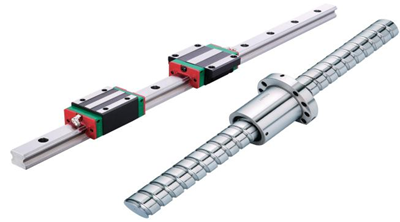

2. The HIWIN guide rail imported from Taiwan and the German WMH rack have high precision and stable operation.

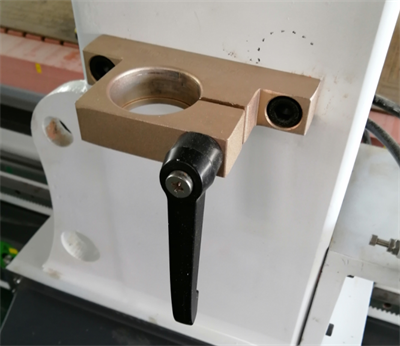

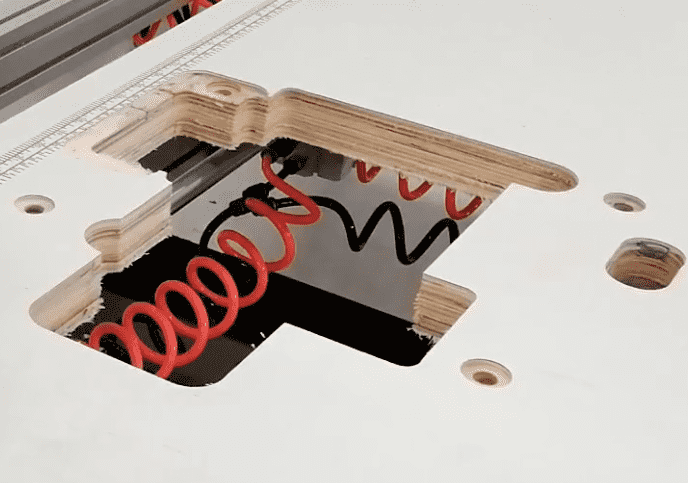

3. Automatic cylinder positioning, high precision; automatic cylinder fixing, more efficient.

4. Air-cooled spindle with automatic tool change, quick tool change, meeting multi-process processing requirements.

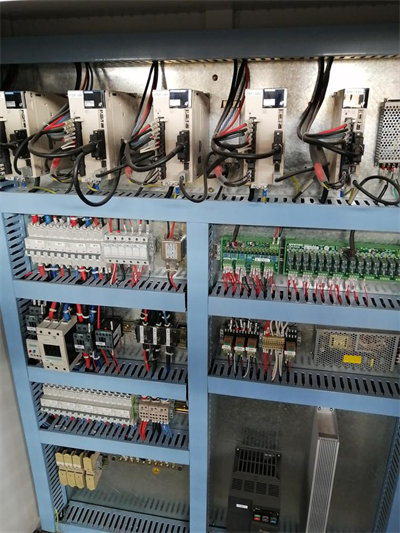

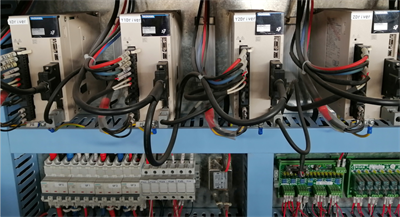

5. Driven by Yaskawa servo motor, strong power and better precision.

6. Can only work offline to get rid of the shackles of the computer

Wood furniture industry:

Doors, Cabinets, Tables, Chairs, Wave plate, fine pattern, antique furniture, wooden door, screen, craft sash, composite gates, cupboard doors, interior doors, headboards, and so on.

Advertising industry:

Signage, Logo, Badges, Display board, Meeting signboard, Billboard

Advertising filed, sign making, acrylic engraving and cutting, crystal word making, blaster molding, and other advertising materials derivatives making.

Application Industry:

Mold industry: various large metalloid mould, especially suitable for automotive foam mold, wooden ship model, wooden model aviation, rail wooden mold, wooden mold train.

| Item | item | value |

| 1 | Model | UW-1325P-2S |

| 2 | Range of Spindle Speed(r.p.m) | 1rpm - 24000rpm |

| 3 | Positioning Accuracy (mm) | 0.01mm |

| 4 | No. of Spindles | Single |

| 5 | Working Table Size(mm) | 1300*2500 |

| 6 | Machine Type | CNC Router |

| 7 | Repeatability (X/Y/Z) (mm) | 0.03mm |

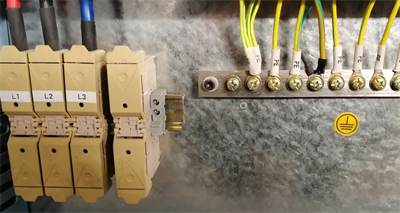

| 8 | Certification | CE |

| 9 | Key Selling Points | Easy to Operate |

| 10 | Marketing Type | Hot Product 2021 |

| 11 | Machinery Test Report | Provided |

| 12 | Video outgoing-inspection | Provided |

| 13 | Speed | Max travelling speed : 60000mm/min

Max working speed : 30000mm/min |

| 14 | Color | Customer Needing |

| 15 | Spindle | HQD/HSD/ Italy air spindle |

| 16 | Control system | DSP controller |

| 17 | X, Y transmission | Germany WMH HERION Rack and gear |

| 18 | Z transmission | Taiwan TBI Ballscrew |

| 19 | Driving Syestm | Japan YASKAWA |

| 20 | XYAC axis | Japan YASKAWA servo motor |

| 21 | Inverter | Taiwan Delta |

| 22 | Motion positioning accuracy | ±0.05mm |

| 23 | Repeated positioning accuracy | ±0.02mm |

| 24 | Weight | 1850kg |

Packing and shipping:

1.Our company specializes in CNC equipment production more than 10 years with rich experience.

2.Our company is a manufacturer, not a trader. have high quality with competitive price.

3.We can provide engineer for overseas service .

4.If there are any problems in the process of using the equipment, you can ask us at any time, and we will try our best to help you solve them.

5.24months warranty and whole life service ,during warranty can provide parts for free.

Our MOQ is 1 set machine, we usually require 10-15 days for manufacturing, 2days for testing well and 1 day for packaging. The exact time will be depended on your order quantity and customized level.

We give customer 2 year quality warranty. if you have any question, we will give permanent technic support and spare parts supplying.

There are english manual or teaching video that show how to use machine. If there is still have any question, please contact us by e-mail / skype/ phone /trademanager online service at any time.

We can produce customized products according to your drawing or samples.

We can help you booking the ship and shipping to your port directly, or we help you search the ship,then you talk with shipping company directly.