Wood CNC router 1325 woodworking engraving cutting machine

1. Large square tube welded bed, more stable and durable

2. The whole bed is milled by a large 5-face milling machining center, which effectively improves the accuracy of assembly

3. Y-axis dual-motor drive, more coordinated and more dynamic

4. The three-axis adopts high-precision imported HIWIN/PMI guide rail and slider, which effectively improves the processing progress

5. used advanced offline control system DSP can get rid of the dependence on the computer for work and improve the utilization of space

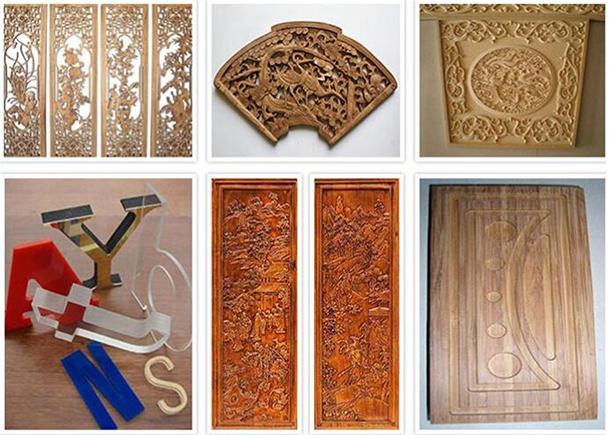

1.Furniture: wooden doors, cabinets, plate, office and wood furniture, tables, chair, doors and windows.

2.Wood products: voice box, game cabinets, computer tables, sewing machines table, instruments.

3.Plate processing: insulation part, plastic chemical components, PCB, inner body of car, bowling tracks, stairs, anti bate board, epoxy resin, ABS, PP, PE and other carbon mixed compounds.

4.Decorate industry: Acrylic, PVC, MDF, artificial stone, organic glass, plastic and soft metals such as copper, alum- inum plate engraving and milling process.

| Model | UW-1325 (UW-1525/UW-1530) |

| Working area | 1300*2500*200mm (1500*2500*200/1500*3000*200mm) |

| Spindle | 3.2kw HQD water cooling spindle |

| Working table | Aluminum T-slot table |

| Transmission mode | Rack pinion on XY axis |

| Z axis Taiwan TBI screw | |

| Dynamic system | Stepper motor (or servo motor according customer requirements) |

| Inverter | Fuling/Delta Brand |

| Control system | DSP A11 |

| Filter | Prevent electromagnetic interference |

| Oiling | Auto oiling system |

| Max working speed | 155m/min |

| Max velocity | 30m/min |

| Spindle speed | 24000rmp |

| Working voltage | AC220/380V 50-60Hz |

| Interface | USB |

| Command language | G code |

| Software environment | Type3/Artcut/Artcam/Ucancam |

| Running environment | Temperature:0-45°C |

Packing:

- First, use stretch film to prevent damp at sea.

- Then use bubble wrap to prevent collision during transportation

- Packing with strong plywood case

- Printer mark on the outside package

Service:

- Warranty:2 years warranty.during warranty ,we can provide the new parts for free.

- Teaching :we provide the manual and video of the machine with machine

- Professional service team can service online ,all of them have more than 7 years experience on the cnc field.

We are the manufacturer and we have more than 10 years factory experience. All machines are produced by ourself , quality can be trusted, and also we have professional engineer team to serve you. We know how to fix the problem in each parts easliy. If you interest, welcome to visit to our factory.

We can given you our best suggestions according your real requirements,then can choose the suitable machine for your real working.

For standard machines, it would be about 7-10 days. For customized machines according to your specific requirements, it would be about 15-20 working days.

After we confirm all details ,then You can pay 30% deposit according the Proforma invoice, then we will start to make production. Once the machine is ready , we will send pictures and video to you, and then you can finish the banlance payment. Finally, we will pack machine and arrange delivery for you as soon as possible.

We have manual and take video teach you how to install the machine, how to use machine, how to let machine work. and so on. Usually we will teach you how to do online like: email or skype or wechat or whatsapp etc. Our engineers have many years of experience for cnc machine service , so he can slove the problem professionally.