High Quality for Automatic Edge Banding Machinery - 5axis Cnc Bridge Saw 4 Axis Stone Cutting Polishing Carving Slab Machinery For Marble Granite Countertops And Sink – UBO

High Quality for Automatic Edge Banding Machinery - 5axis Cnc Bridge Saw 4 Axis Stone Cutting Polishing Carving Slab Machinery For Marble Granite Countertops And Sink – UBO Detail:

1. Compact size without needing the ground base.

2. With advanced touch Touch operation CNC control system and all pattern operation, the machine can be operated without professional operators.

3. With powerful functions, the machine can work almost all the jobs of a small factory.

4. With less electricity and more efficiency, the cost is decreased much.

5. High quality accessories and electric parts are used to secure long service life and low cost.

6. intelligent processing cross-border protection, to prevent the mechanical impact due to excessive design documents processing.

7. Diversity control can separately control the processing speed, idling speed, cutting speed, greatly improving the quality of speed, greatly improving the quality of speed, greatly improving the quality of processed product and processing efficiency.

Full automatic five axis infrared bridge cutting machine, multi language conversion, table processing by one machine, x-y-z-a-b five axis linkage, more widely used, simple operation and stronger practicability.

Used for cutting, chamfering, edge grinding, slotting, drilling, circular arc and other special-shaped processing.

| Model | US-B3020 |

| Programming method 1 | CAD image input & Manual programming |

| Control method | CNC |

| Power | 7.5KW (optional 4KW / 11KW) |

| Working voltage | 380V 3phase (customized) |

| R.P.M | 6000r/min |

| Blade size | 400mm |

| X-axis working stroke | 3000mm |

| Y-axis working stroke | 2000mm |

| Z-axis working stroke | 400mm |

| A-axis working stroke | 360° free rotation |

| B-axis working stroke | 0-90° |

| X/Y-axis cutting speed | 1-2000mm/min |

| Z-axis cutting speed | 1-1000mm/min |

| A cutting speed | 0-7r/min |

| Cutting thickness | 100mm |

| Processing precision | 0.2mm |

| Working table size | 3000x2000mm |

| Overall size | 5500x3120x3320mm |

| Weight | 3200KG |

1. Outside package: Standard marine export plywood case.

2. Inner package: Three layers in total; EPE pearl cotton film+PE stretchy film.

Improved package, much more strong and environmental protection.

We can also make package according to your requests.

Delivery Detail: Shipped in 20-30 working days after payment.

1. service before sales: our sales will communicate with you to know your requirements about the cnc router specification and what kind of work you will do, then we will offer our best solution for you. So that it can confirm each customer get their real needed machine.

2. service during production: we will send photos during manufacturing, so customers can know more details about the procession of making their machines and give their suggestions.

3. service before shipping: we will take photos and confirm with customers the specifications of their orders to avoid the mistake of wrong making machines.

4. service after shipping: we will write to customers in time when the machine departs, so customers can make enough preparation for the machine.

5. service after arrival: we will confirm with customers if machine is in good condition, and see if there is any spare part missing.

6. service of teaching: there are some manual and videos about how to use machine. If some customers have further question about it, we have professional technician to help install and teach how to use through Skype, calling, video, mail or remote control, etc.

7. service of warranty: we offer 12 month warranty for whole machine. If any fault of the machine parts within warranty period, we will replace it for free.

8. service in long-term: we hope every customer can use our machine easily and enjoy using it. If customers have any problems of machine in 3 or more years, please contact us freely.

Q1: How can I get an accurate price?

Please tell us your cutting material and the working size.

Q2: How is your after sales service?

Our sales are online for 24-hours. We can also supply overseas install service. Also we have more than 10 countries warehouse and department.

Q3: How long is the delivery time?

Generally 15 ~ 25 working days.

Q4: Can I get a machine according to my own requirements?

Sure.We accept OEM and ODM

Q5: If my machine is broken. Can you repair it for me?

Yes. We have free traning online. If there is big trouble with your machine in the warrenty time, we can repair it.

Q6: How is the quality of your machine?

Our machine adopts heavy lathe bed, and each part is processed by CNC machining center, which greatly improves the accuracy of machine operation.

Cypcut professional cutting system.The operating system can realize intelligent layout of graphics cutting and support the import of multiple graphics, optimizing cutting orders automatically, searching edges smartly and automatic positioning. Control system adopts the best logic programming and software interaction, provides stunning operation experience, effectively enhancing the utilization of sheet metal and reducing waste. Simple and fast operation system, efficient and accurate cutting instructions, effectively improve the user experience.

Rotary device

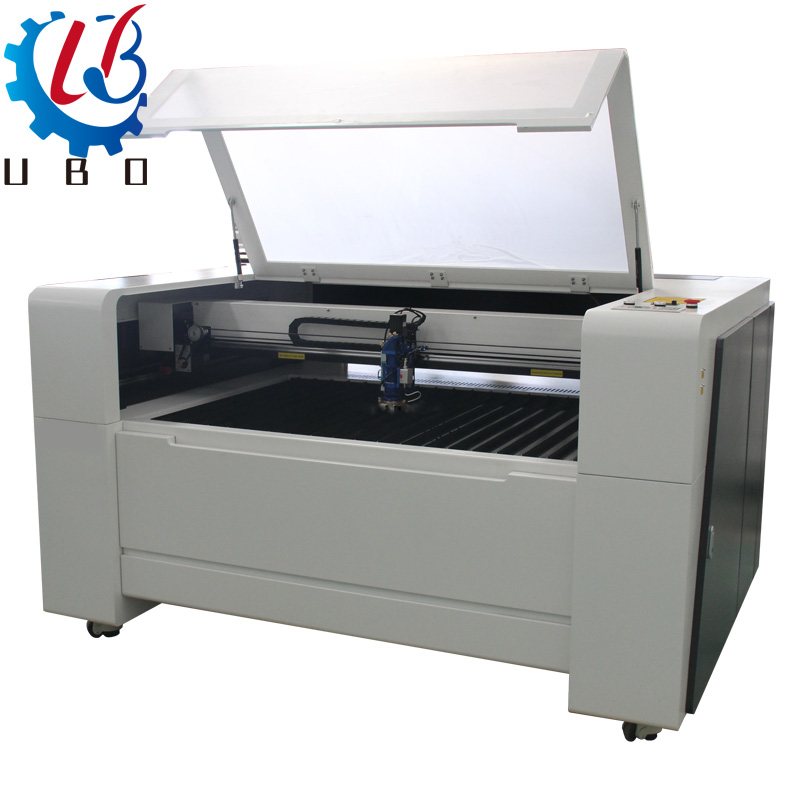

Product detail pictures:

Related Product Guide:

We have now sophisticated machines. Our solutions are exported to the USA, the UK and so on, enjoying a great reputation amid consumers for High Quality for Automatic Edge Banding Machinery - 5axis Cnc Bridge Saw 4 Axis Stone Cutting Polishing Carving Slab Machinery For Marble Granite Countertops And Sink – UBO , The product will supply to all over the world, such as: Rome, Turkmenistan, Canada, Based on our guiding principle of quality is the key to development, we continually strive to exceed our customers' expectations. As such, we sincerely invite all interested companies to contact us for future cooperation, We welcome old and new customers to hold hands together for exploring and developing; For more information, be sure to feel free to contact us. Thanks. Advanced equipment, strict quality control, customer-orientation service, initiative summary and improvement of defects and extensive industry experience enable us to guarantee more customer satisfaction and reputation which, in return, brings us more orders and benefits. If you are interested in any of our merchandise, make sure you feel free to contact us. Inquiry or visit to our company are warmly welcome. We sincerely hope to start a win-win and friendly partnership with you. You can see more details in our website.

This company conforms to the market requirement and joins in the market competition by its high quality product, this is an enterprise that have Chinese spirit.